The steel wire buckle is formed by large-scale mechanical stamping. After galvanized surface treatment, it has extremely strong tensile ability. It is the most ideal metal packaging buckle for flexible packaging belts such as fiber packaging belts, PP belts, PET belts, and woven belts.

Choosing a good steel wire packaging buckle is an attitude! It can effectively ensure the safety of packaging and transportation of goods. A good steel wire packaging buckle cannot do without strict and standardized production standards.

Firstly, advanced production equipment and experienced workers are required, both of which are indispensable.

Secondly, it is necessary to ensure the quality of the production products, which requires a complete and systematic quality inspection process.

Finally, while ensuring production standardization, it is necessary to ensure that the surface treatment technology of the steel wire packaging buckle is qualified, so that our productsnot only can be used, but also beautiful!

Product Raw Material: Steel Wire Surface Treatment Type: Galvanized, Phosphated

The return type wire buckle has the following characteristics:

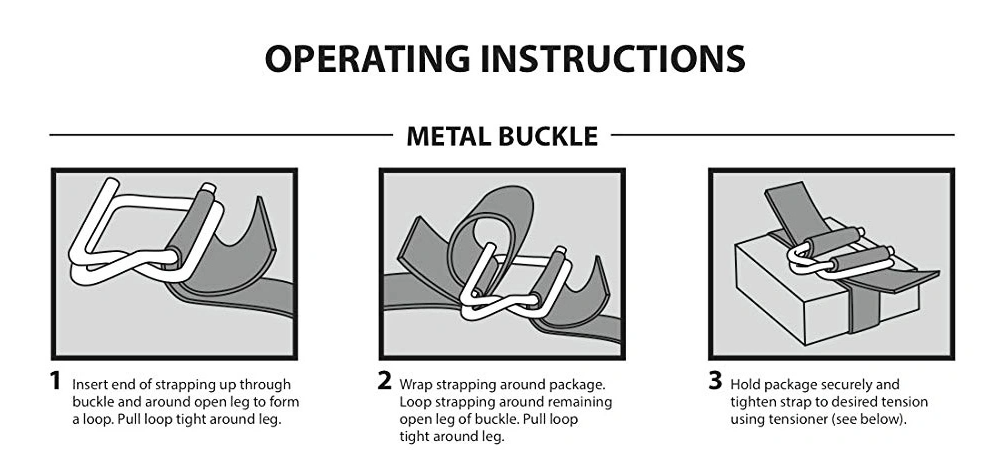

1. With the help of a tensioner, the operation is convenient and simple;

2. Can be used for bundling large objects, such as aluminum ingots, wood, steel, and stone;

3. It can also be used for bundling large objects on flatbed trucks or pallets, logistics containers, etc;

4. Strong tensile force, after multiple tensile tests, the maximum system tensile force of this model product can be determined to be 4.5T;

5. Suitable for various types of packaging tapes, such as PP tape, PET tape, woven tape, polyester fiber flexible packaging tape, etc;

The advantages of the WIRE BUCKLE also include:

1. Connection efficiency up to 90%

2. The most stable fastening method in the industry

3. Self locking type

4. Made of high-quality steel wire

5. Available in different sizes and strength models

Due to the above advantages and characteristics, the return type packaging buckle is widely used in packaging industries such as containers, large machinery, glass, pipe fittings, oil drums, steel, wood, papermaking, chemical industry, etc., greatly improving the work efficiency of customer companies and saving them costs.