In the modern logistics and packaging industry, safe, efficient, and environmentally friendly packaging solutions have always been the primary goals pursued by enterprises. With technological advancements and heightened environmental awareness, the composite strap, as a novel eco-friendly material, has gradually emerged as a highly regarded safe bundling tool in the market due to its exceptional bundling performance, high-strength load-bearing capacity, and recyclability. This article delves into the application of composite straps across various sectors and how they play a pivotal role in ensuring safe bundling.

The composite strap, as the name suggests, is a bundling and strapping material made primarily from high-strength fibers through specialized processes. Compared to traditional metal or plastic strapping, the composite strap boasts several notable advantages:

1.High Strength and Toughness: Crafted from premium fibers, it exhibits remarkable tensile strength and elongation at break, enabling it to withstand significant external forces without breaking, thereby safeguarding cargo during transportation.

2.Lightweight: Lighter than metal strapping, the composite strap facilitates handling and reduces logistical costs and labor intensity.

3.Eco-friendly and Recyclable: Most composite straps are biodegradable or easily recyclable, aligning with current green packaging trends and minimizing environmental impact.

4.Water and Corrosion Resistance: Its excellent water resistance and corrosion resistance ensure stable performance in harsh environments, prolonging its service life.

5.Ease of Operation: When paired with specialized tools, the composite strap allows for swift and convenient bundling, enhancing work efficiency.

1.Heavy Cargo Bundling: For large machinery, building materials, steel, and other heavy cargo, the composite strap provides reliable fixing and bundling solutions, preventing shifting or damage during transportation.

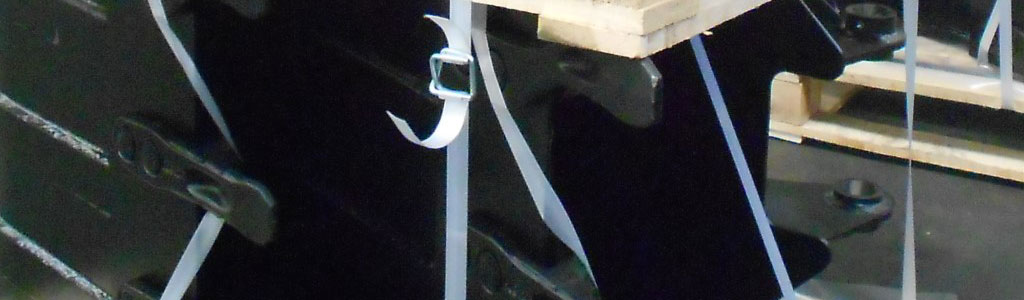

2.Carton and Wooden Box Packing: In e-commerce, manufacturing, and other sectors, the composite strap is commonly used to reinforce cardboard boxes and wooden crates, ensuring goods remain intact during stacking and transportation.

3.Cold Chain Logistics and Fresh Food Delivery: For perishable goods requiring low temperatures, the composite strap offers secure bundling while its eco-friendly material minimizes potential impacts on food quality, safeguarding food safety.

4.Hazardous Materials Transportation: In this field, the composite strap's non-sparking and corrosion-resistant properties make it an essential packaging aid, enhancing safety during transportation.

1.Reduced Cargo Damage: Through tight and even bundling, the composite strap effectively prevents cargo from shaking and colliding during transportation, significantly lowering damage rates and preserving cargo value.

2.Enhanced Transportation Efficiency: Stable bundling ensures cargo remains secure during loading, unloading, and transportation, reducing stoppages for reorganization and enhancing overall efficiency.

3.Improved Safety: In emergency braking or turns, the composite strap prevents cargo from shifting, mitigating the risk of accidents involving vehicles and personnel, ensuring safe transportation.

4.Environmental Contribution: Using recyclable or biodegradable composite straps reduces plastic waste, contributing to green logistics and sustainable development.

As global environmental concerns intensify and the logistics industry continues to expand, the composite strap, as a high-strength, eco-friendly, and easy-to-use packaging material, boasts a promising future. With technological advancements and cost reductions, the composite strap is poised to gain wider adoption across multiple sectors, becoming an indispensable component of modern logistics packaging. Furthermore, enterprises should innovate continuously, developing more market-responsive and superior composite strap products to contribute to the greening and intelligentization of the logistics industry.

In conclusion, the composite strap, with its unique safe bundling capabilities and environmental benefits, is gradually transforming the traditional packaging industry, offering safer, more efficient, and eco-friendly solutions for modern logistics and transportation.