In today’s world, waste management has become a critical concern for businesses, municipalities, and environmental organizations. With increasing volumes of waste being generated daily, efficient waste compaction and recycling processes are essential to reduce environmental impact and optimize resource utilization. One often-overlooked yet vital component in this process is **baling tape**. This durable, high-strength material plays a significant role in enhancing the efficiency of compactor waste management systems. In this article, we will explore how baling tape contributes to efficient waste compaction, its benefits, and its applications in modern recycling operations.

## The Role of Compactors in Waste Management

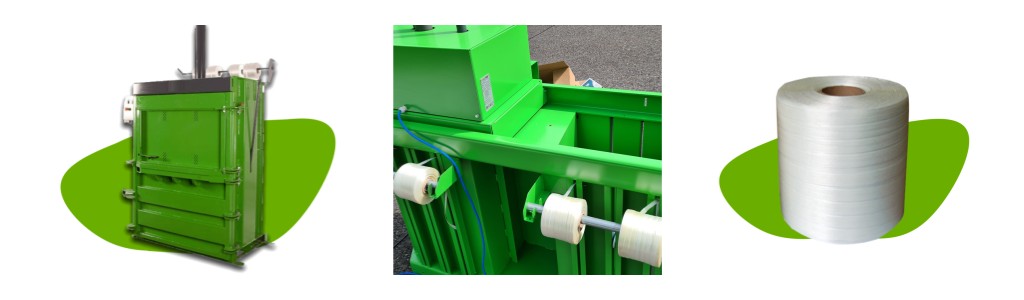

Compactors are machines designed to compress waste materials into dense, manageable bundles. They are widely used in industries such as recycling, manufacturing, retail, and logistics to reduce the volume of waste, making it easier to transport, store, and process. Commonly compacted materials include cardboard, plastics, paper, textiles, and metals. By reducing the size of waste, compactors help lower transportation costs, minimize landfill usage, and improve recycling efficiency.

However, the effectiveness of a compactor depends not only on the machine itself but also on the materials used to secure the compacted waste. This is where baling tape comes into play.

## What is Baling Tape?

Baling tape, also known as Baling Press Strap or Baler Banding, is a heavy-duty material used to bind and secure compacted waste into bales. It is typically made from materials such as polypropylene, polyester, each offering unique properties suited to different types of waste and compaction needs. Baling tape is designed to withstand high tension, resist abrasion, and endure harsh environmental conditions, making it an ideal choice for securing bales in recycling and waste management operations.

## Benefits of Using Baling Tape in Compactor Waste Management

### 1. **Enhanced Bale Stability**

One of the primary functions of baling tape is to ensure that compacted waste remains tightly bound during handling, transportation, and storage. High-quality baling tape prevents bales from loosening or falling apart, which can lead to spills, safety hazards, and inefficiencies in the recycling process. By maintaining bale integrity, baling tape helps streamline operations and reduces the risk of costly disruptions.

### 2. **Improved Transportation Efficiency**

Compacted waste secured with baling tape takes up less space, allowing more material to be transported in a single trip. This not only reduces transportation costs but also lowers fuel consumption and carbon emissions, contributing to more sustainable waste management practices.

### 3. **Versatility Across Materials**

Baling tape is suitable for a wide range of waste materials, including cardboard, plastics, paper, and metals. Its versatility makes it a valuable tool for recycling facilities that handle diverse types of waste. For example, polypropylene baling tape is ideal for lightweight materials like cardboard, while steel baling tape is better suited for heavy-duty applications such as metal recycling.

### 4. **Cost-Effectiveness**

Investing in high-quality baling tape can lead to significant cost savings over time. By reducing waste volume and improving transportation efficiency, businesses can lower their operational expenses. Additionally, durable baling tape minimizes the need for frequent re-baling or repairs, further reducing costs.

### 5. **Environmental Benefits**

Using baling tape in compactor waste management supports recycling efforts by ensuring that materials are securely bound and ready for processing. This helps divert waste from landfills and promotes the reuse of valuable resources. Furthermore, some baling tapes are made from recyclable materials, aligning with the principles of a circular economy.

## Applications of Baling Tape in Compactor Waste Management

### 1. **Recycling Facilities**

Recycling centers rely on compactors and baling tape to process large volumes of recyclable materials. For instance, cardboard and paper waste are compacted into bales and secured with baling tape before being sent to paper mills for recycling. Similarly, plastic bottles and containers are baled and transported to facilities where they are processed into new products.

### 2. **Retail and Distribution Centers**

Retailers and distribution centers generate significant amounts of cardboard waste from packaging materials. Compactors and baling tape are used to manage this waste efficiently, reducing storage space requirements and lowering disposal costs.

### 3. **Manufacturing Plants**

Manufacturing facilities often produce scrap materials such as metal shavings, plastic offcuts, and fabric remnants. These materials are compacted and baled for recycling or resale, with baling tape ensuring that the bales remain intact during handling and transportation.

### 4. **Waste Management Companies**

Waste management companies use compactors and baling tape to process municipal solid waste, commercial waste, and industrial waste. By compacting and baling waste, these companies can optimize their operations and provide more cost-effective services to their clients.

## Choosing the Right Baling Tape

Selecting the appropriate baling tape for your compactor waste management needs is crucial for achieving optimal results. Consider the following factors when choosing baling tape:

- **Width and Thickness:** The width and thickness of the baling tape should match the size and weight of the bales being secured. Wider and thicker tapes provide greater strength and stability for larger bales.

- **Environmental Conditions:** If the bales will be exposed to moisture, UV radiation, or extreme temperatures, choose baling tape that is resistant to these conditions.

## Conclusion

Baling tape is an indispensable tool in modern compactor waste management systems. Its ability to secure compacted waste into stable, transportable bales enhances efficiency, reduces costs, and supports environmental sustainability. Whether you operate a recycling facility, a retail distribution center, or a manufacturing plant, incorporating high-quality baling tape into your waste management process can deliver significant benefits.

As the demand for efficient and sustainable waste management solutions continues to grow, baling tape will remain a key component in helping businesses and organizations achieve their recycling and waste reduction goals. By understanding its importance and selecting the right type of baling tape for your needs, you can optimize your compactor operations and contribute to a cleaner, greener future.