In the modern logistics and transportation industry, the safe and efficient bundling and securing of heavy cargo has always been a prime concern. With technological advancements and evolving market demands, Woven Cord strapping, as an innovative and efficient binding material, is gradually gaining popularity among logistics professionals. This article will explore the characteristics, applications, advantages, and future development of Woven Cord strapping.

I. Characteristics of Woven Cord Strapping

Woven Cord strapping is a tape-like product made from high-strength fiber materials, exhibiting the following distinctive characteristics:

1.High strength: Woven Cord strapping is woven from robust fiber materials like polyester and nylon, providing excellent tensile strength and tear resistance, capable of enduring the immense pressure of heavy cargo.

2.Lightweight and flexible: Compared to traditional binding materials like metal chains and steel belts, Woven Cord strapping is lighter in weight and more flexible, facilitating portability and handling while adapting to various complex bundling needs.

3.Wear-resistant and corrosion-resistant: The surface of Woven Cord strapping undergoes special treatment, resulting in superior wear and corrosion resistance, enabling it to withstand harsh transportation environments for extended periods.

4.Reusable: Woven Cord strapping exhibits good durability and reusability. With simple cleaning and maintenance, it can be used multiple times, reducing logistics and transportation costs.

II. Applications of Woven Cord Strapping

Woven Cord strapping has extensive applications in the logistics and transportation industry, including:

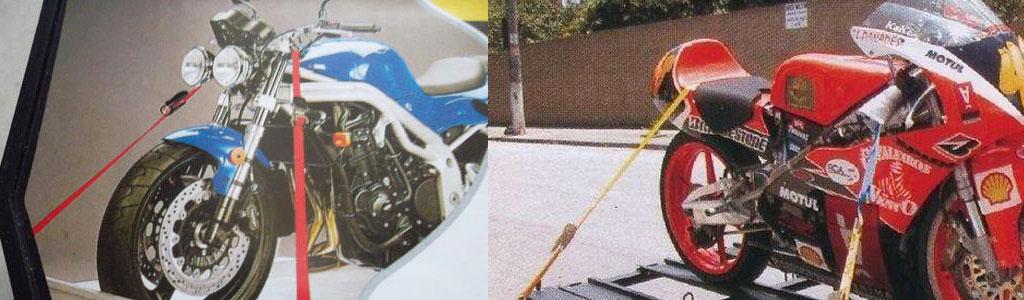

1.Cargo bundling and securing: Woven Cord strapping is used to bundle and secure various heavy cargoes, such as machinery, steel, and timber, ensuring stability and safety during transportation.

2.Container securing: In container transportation, Woven Cord strapping is used to secure cargo within containers, preventing movement or collapse due to vibration.

3.Lifting operations: Woven Cord strapping can be used as lifting belts to safely and stably lift heavy equipment or cargo.

4.Ship mooring: In ship mooring operations, Woven Cord strapping is used to secure the ropes between ships and docks, ensuring stability in rough seas.

III. Advantages of Woven Cord Strapping

Compared to traditional binding materials, Woven Cord strapping offers the following significant advantages:

1.Enhanced safety: The high strength and flexibility of Woven Cord strapping ensure the stability and safety of cargo during transportation, reducing the risk of damage and injuries.

2.Reduced transportation costs: The lightweight and durable nature of Woven Cord strapping lowers material consumption and labor costs in logistics and transportation. Its reusability further reduces overall costs.

3.Improved transportation efficiency: Woven Cord strapping is easy to carry and operate, enabling rapid cargo bundling and securing, thus enhancing transportation efficiency and speed.

4.Environmental friendliness: Made from environmentally friendly materials, Woven Cord strapping does not pollute the environment. Its reusability also reduces waste generation, aligning with modern environmental protection concepts.

IV. Future Development of Woven Cord Strapping

With the continuous evolution of modern logistics and transportation industries, the application prospects for Woven Cord strapping will become broader. In the future, Woven Cord strapping is expected to evolve towards higher strength, lighter weight, and greater environmental friendliness. Additionally, with the integration of intelligent and automated technologies, the operation of Woven Cord strapping will become more convenient and efficient. As new materials and processes emerge, the performance and quality of Woven Cord strapping will continue to improve.